Extrusion Coating & Lamination

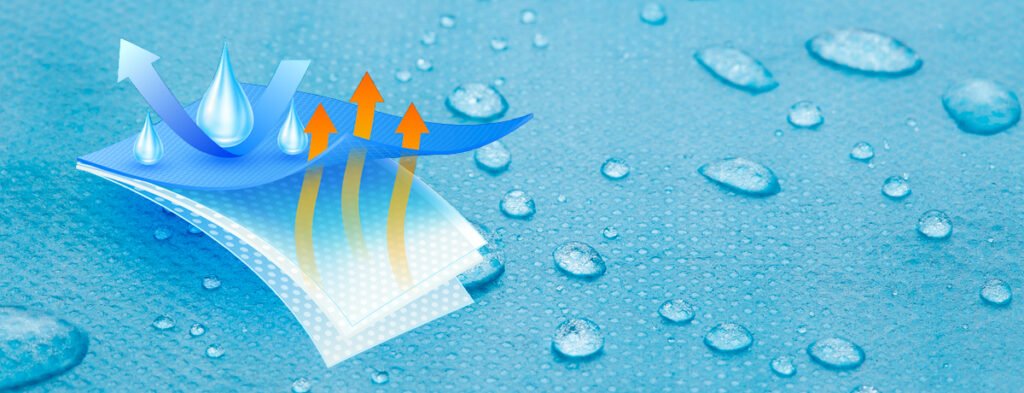

Get StartedFor products that need fluid resistance, breathability, and multilayer protection, Manjushree Spntek offers advanced extrusion coating and lamination. Our in-house systems bond nonwovens with functional layers to deliver barrier strength, thermal control, and surface performance — ideal for medical, industrial, and construction-grade fabrics.

Capabilities

Bi- and Tri-layer Lamination

Details

GSM Range

Details

Width Range

Details

Breathable & Non-breathable

Details

Substrate Compatibility

Details

NIL

Details

Capabilities

- Bi- and Tri-layer Lamination

Combine multiple substrates (Spunbond, Spunmelt, Films) to create structured, breathable, or sealed fabrics - GSM Range: 10–350 GSM

- Width Range: Up to 3.2 meters

- Breathable & Non-breathable Options available

- Substrate Compatibility: Medical-grade films, PP nonwovens, membranes

I am a heading

Surgical gowns and chemotherapy apparel

Breathable medical laminates

Raincoats, coveralls, protective jackets

Table and chair covers

Concrete curing blankets

Printed tarpaulins, wraps, and industrial sheets

I am a heading

Single-site control = lower lead times, better consistency

Seamless integration with Smart Spunmelt and A.Celli-treated fabrics

Cleaner packaging and handling post-coating

Fast scaling for bulk orders across multiple applications

I am a heading

- Fluid Resistance & Breathability: For AAMI Level 3/4 gowns, drapes, and chemo protection

- Thermal Control: For use in insulation and protective wear

- Structural Strength: For industrial covers, PPE, and wraps

- Aesthetic Finishes: Compatible with printed layers and treated top sheets

Need a durable, coated fabric that resists fluids and stands up to wear?

We’ll laminate and finish it in-house — the way your industry demands.