Improved Weight Consistency

Fabrics produced on Reicofil machines deliver upto 30% improved weight consistency as compared to Chinese lines.

Non-stop production

Inconsistency leads to the risk of halting the conversion process while making end products while our seamless fabric ensures non-stop production.

More Profits

It might also lead to overuse of material during the manufacturing process while the fabric made on the Reicofil line has less than 2% inconsistency allowing you to get the output as per planning ensuring full production and profits.

More Savings

It saves money, time and resources as the entire end-product production process need not be stopped to report an error and start the process all over again.

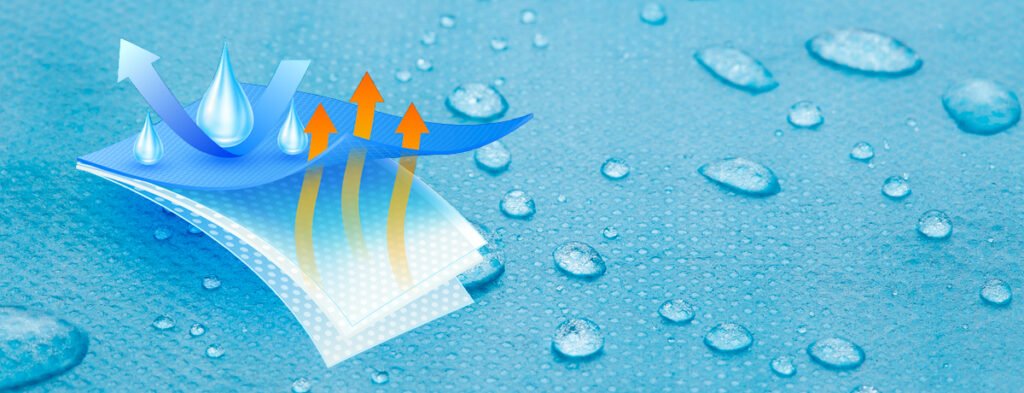

Lighter, Stronger, Better

The Reicofil technology ensures optimal meltblown content while producing spunmelt fabric which in return offers better protection. Even our 35 GMS fabric with improved barrier can offer better protection and performance compared to that of some other 45 GSM material made with some other inferior method or technology.